-

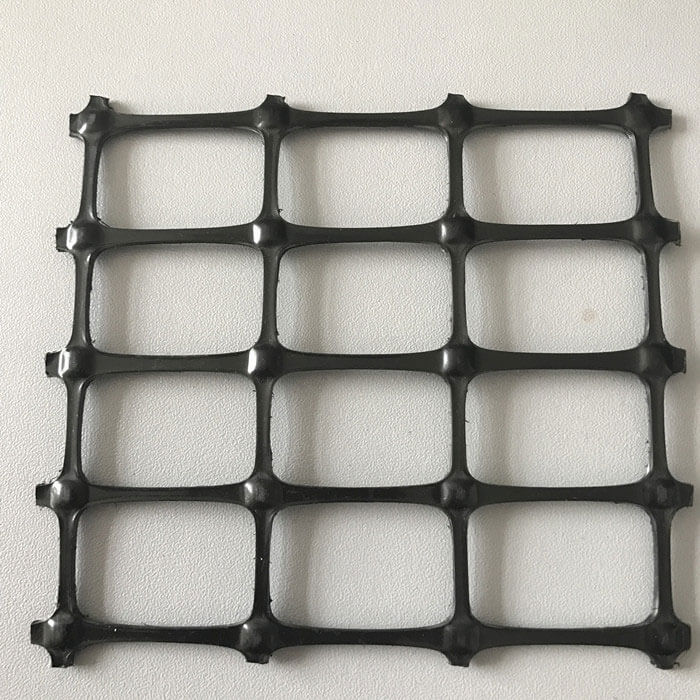

PP BX GEOGRID

PP BX GEOGRID is made from PP resin as its raw material, produced through extruding, punching, heating, longitudinal stretching, transverse stretching.

1. Material: The plastic netting is processed and made of polyethylene and polypropylene.

2. Colors: orange, green, black, etc.

3. Width: 90 - 250cm, Opening is from4-100mm, thickness from 1mm to 10mm

4. Weight: not less than 120g/sqm -

Extruded PP Biaxial Geogrid

Extruded PP Biaxial Geogrid is used in base reinforcement applications such as roads, storage yards and parking lots. The properties of Extruded PP Biaxial Geogrid, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

-

BX Polypropylene Grid

BX Polypropylene Grid is made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material. The reinforcing action of PP Biaxial Geogrids lies mainly in confining soil and increasing its shearing resistance by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost. PP Biaxial Geogrids can be used with any kind of mechanical fill material. Two aperture size ranges are available for optimum matching with project fill. Standard Roll Dimensions.

-

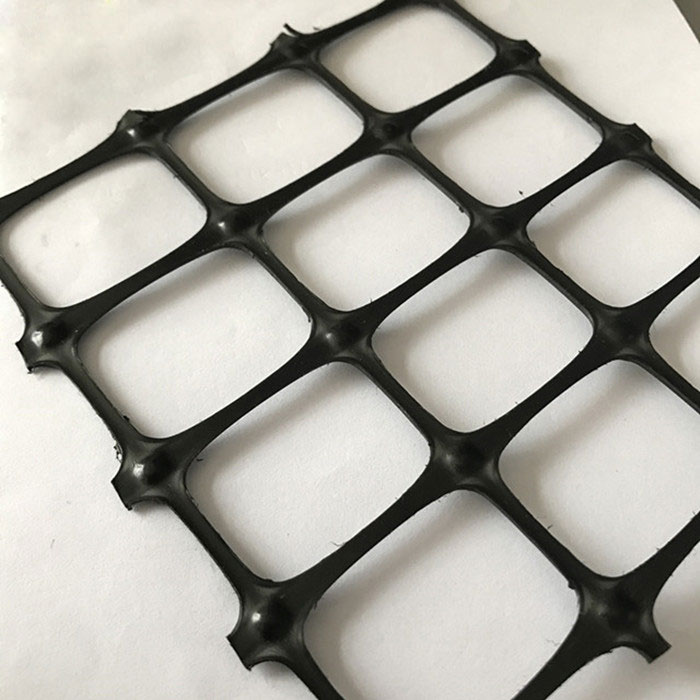

Biaxial Geogrid BX1200

PP Biaxial Geogrid is an integrally formed structure, which especially designed for soil stabilization and reinforcement applications. EltGrid-PPBG biaxial geogrid is manufactured from Polypropylene, from the process of extruding, longitudinal stretching and transverse stretching.

-

Road Construction Biaxial Geogrid

Road Construction Biaxial Geogrid is an integrally formed structure, which especially designed for soil stabilization and reinforcement applications. EltGrid-PPBG biaxial geogrid is manufactured from Polypropylene, from the process of extruding, longitudinal stretching and transverse stre tching.

-

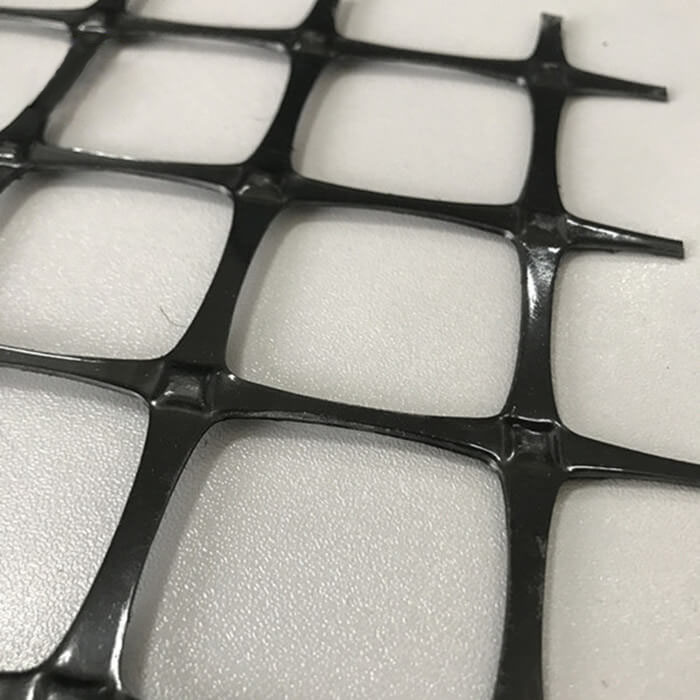

PP Plastic Biaxial Geogrid

PP Plastic Biaxial Geogrid has the characteristics of high tensile strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long service life etc., can be widely used in maintenance of the old cement pavement, airport runway, dam, the river bank, slope protection, bridge engineering and fields of enhancement processing and so on, can strengthen for the road surface, reinforcing, prevent pavement fatigue crack, hot cold expansion crack and the reflection crack, and can scatter pavement bearing stress, extend the service life of pavement, high tensile strength and low elongation...

-

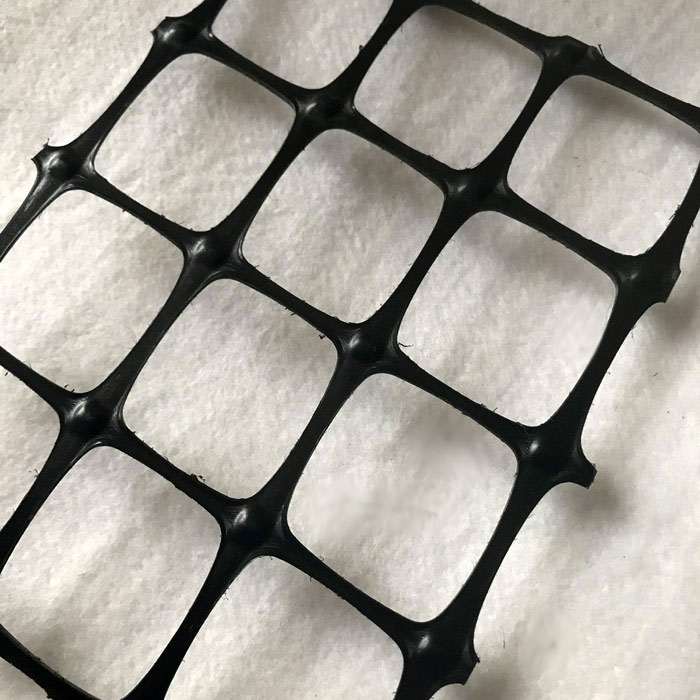

Polyester Biaxial Geogrid

Polypropylene Biaxial Geogrid is made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material. The reinforcing action of PP Biaxial Geogrids lies mainly in confining soil and increasing its shearing resistance by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost. PP Biaxial Geogrids can be used with any kind of mechanical fill material.

-

Plastic BX GEOGRID

Plastic bx geogrid is made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material. PP Plastic Biaxial Geogrids lies mainly in confining soil and increasing its shearing resistance by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost.

PP Biaxial Geogrid

- Products Geogrid Composite Geogrid Geotextile HDPE Geocell Geomembrane Composite Geomembrane HDPE GeonetDrainage GeocompositeErosion Control Mat

- Contact Us

- General Manager: Allen Mobile: +86 13854820689 Email: lianyiallen@126.com; chgeogrid@163.com WhatsApp +8613854820689 Wechat: 0086 13854820689 Skype: chgeogrid@hotmail.com

- Sales Director: Alice Mobile: +86 18953872761 Email: sdlianyigeogrid@hotmail.com Whatsapp: +86 18953872761 Wechat: 0086 18953872761

العربية

العربية Français

Français 한국어

한국어 Русский

Русский Español

Español English

English