- Home

- Products

- Geomembrane

- HDPE Geomembrane

- Waterproofing Geomembrane HDPE

Quantity

Waterproofing Geomembrane HDPE

Description

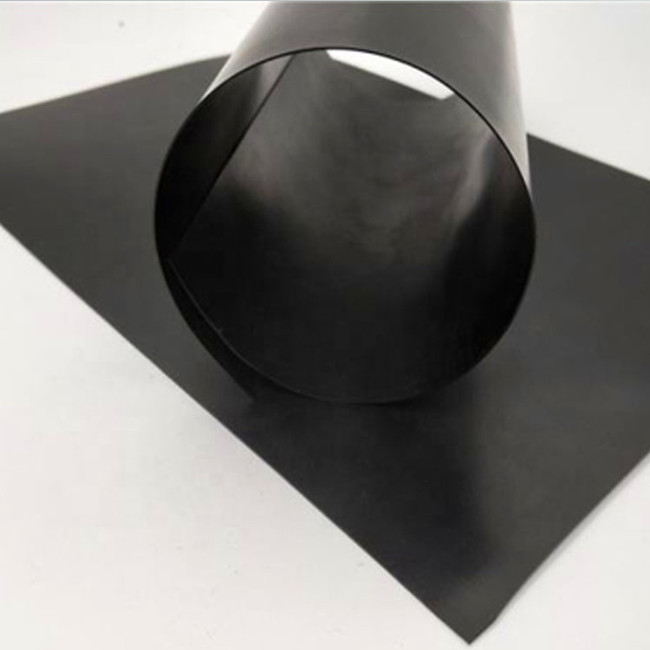

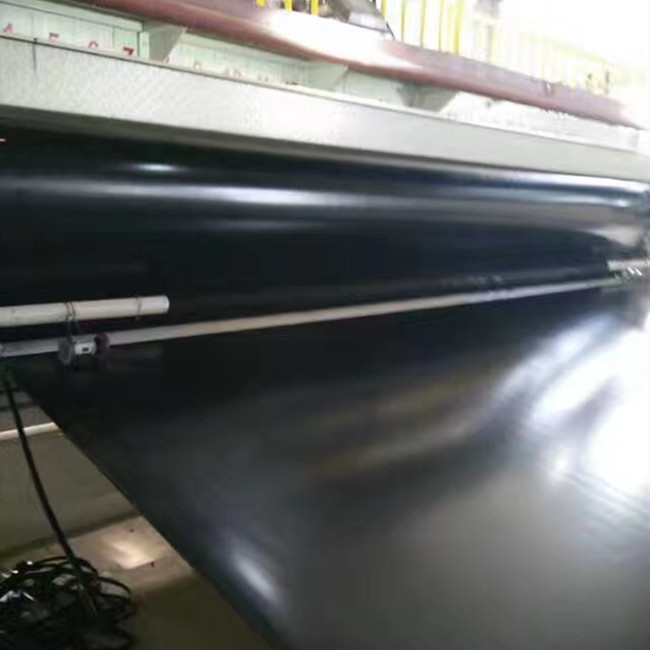

Waterproofing geomembrane hdpe is the most common field fabricated geomembrane material used for environmental containment liners.

Description of Waterproofing Geomembrane HDPE

Waterproofing geomembrane hdpe are the most widely used products for solid waste containment (such as landfill liners), mining, and water containment applications.

our factory uses the highest quality resins to manufacture the widest selection of high density polyethylene (HDPE) and linear low density polyethylene (LLDPE) geomembrane products available in either a black, green, white or Conductive upper surface, and in either a smooth or textured single or double-sided surface.

Specification of Waterproofing Geomembrane HDPE

| Properties | Test Method | HDPE-Smooth | ||||

| Thickness(min.ave.) | ASTM D 5199 Mm(mil) | 0.75(30) | 1.00(40) | 1.5(60) | 2.0(80) | 2.5(100) |

| Density | Density ASTM D 792 g/cm3 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 |

| Tensile Properties(min.ave.) | ASTM D 638 Tipo IV | |||||

| Yield Strength | Kn/M(lb/in) | 11(63) | 15(84) | 22(126) | 29(168) | 37(210) |

| Break Strength | Kn/M(lb/in) | 20(114) | 27(152) | 40(228) | 53(304) | 67(380) |

| Yied Elongation | % | 12 | 12 | 12 | 12 | 12 |

| Break Elongation | % | 700 | 700 | 700 | 700 | 700 |

| Tear Resistance(min.ave.) | ASTM D 1004 N(lb) | 93(21) | 125(28) | 187(42) | 249(56) | 311(70) |

| Puncture Resistance(min.ave.) | ASTM D 4833 N(lb) | 240(54) | 320(72) | 480(108) | 640(144) | 800(180) |

| Carbon Black Content | Carbon Black Content ASTM D 1603 (%) | 2~3 | 2~3 | 2~3 | 2~3 | 2~3 |

- Products Geogrid Composite Geogrid Geotextile HDPE Geocell Geomembrane Composite Geomembrane HDPE GeonetDrainage GeocompositeErosion Control Mat

- Contact Us

- General Manager: Allen Mobile: +86 13854820689 Email: lianyiallen@126.com; chgeogrid@163.com WhatsApp +8613854820689 Wechat: 0086 13854820689 Skype: chgeogrid@hotmail.com

- Sales Director: Alice Mobile: +86 18953872761 Email: sdlianyigeogrid@hotmail.com Whatsapp: +86 18953872761 Wechat: 0086 18953872761

العربية

العربية Français

Français 한국어

한국어 Русский

Русский Español

Español English

English