- Home

- Products

- Composite Geogrid

- Composite PP Biaxial Geogrid with Nonwoven Geotextile

- Heat Bonded Geogrid With Geotextile

Heat Bonded Geogrid With Geotextile

Description

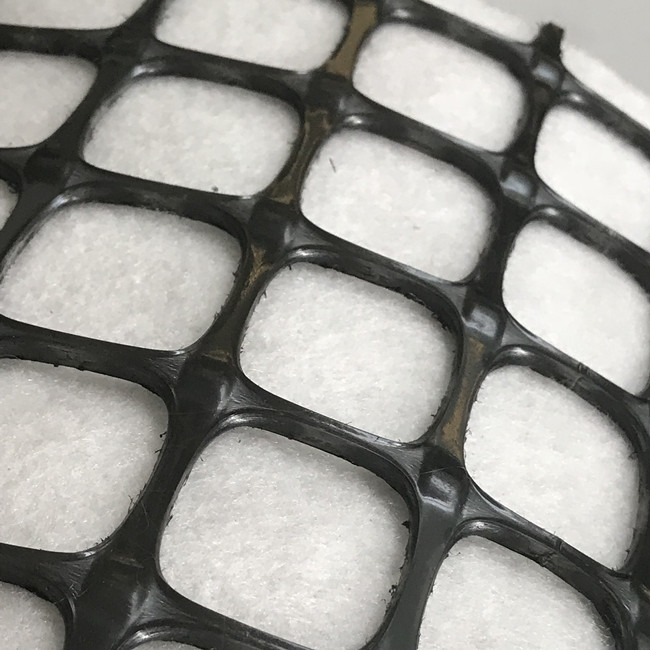

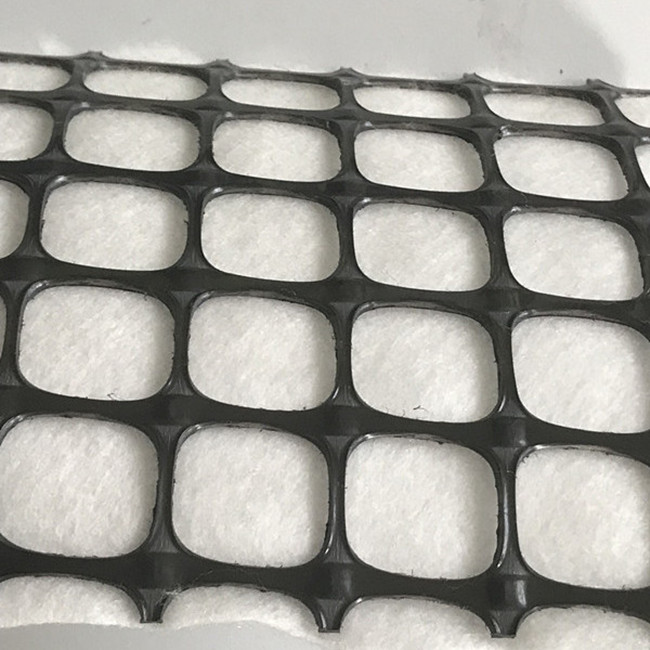

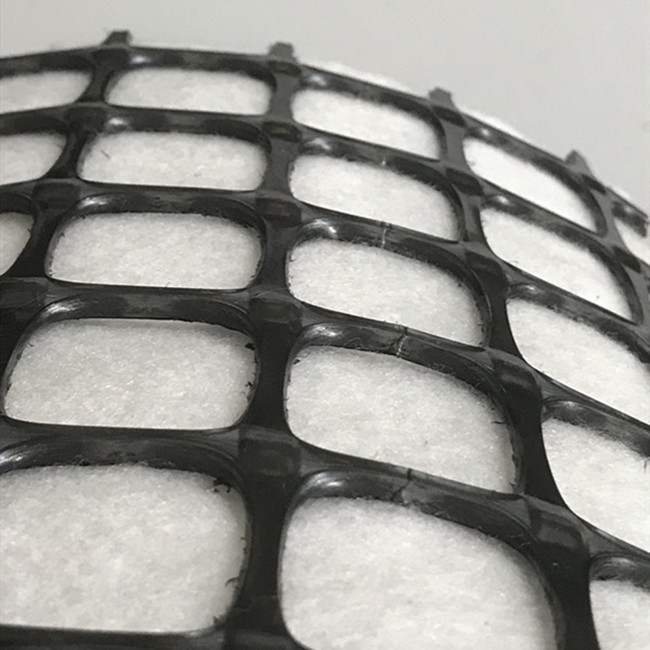

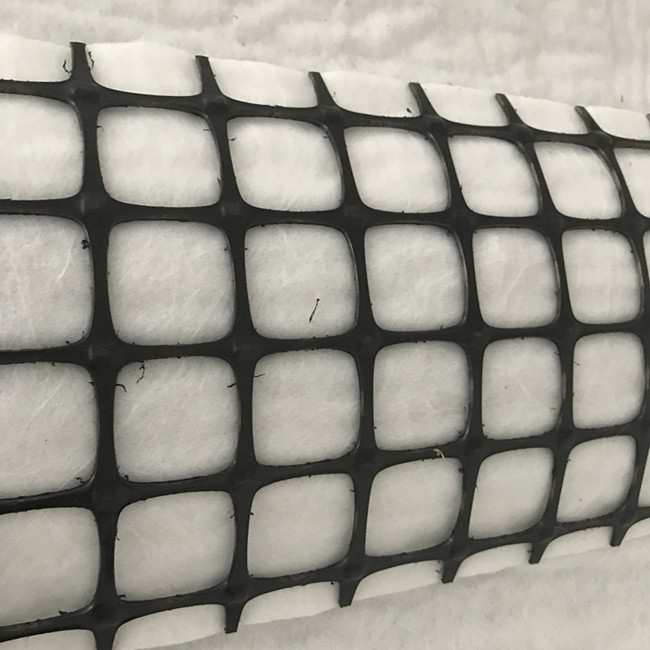

Heat Bonded Geogrid With Geotextile is manufactured by bonding a Biaxial Geogrid to a nonwoven polyester or PP nonwoven geotextile.

Description of Heat Bonded Geogrid With Geotextile

Heat Bonded Geogrid With Geotextile consists of BX geogrid and nonwoven geotextile, they become a whole body by heat bonding process.

High intension, high tenacity, high occlusive force with soil or gravel, erosion-resistant, water drainage, light weight Reinforce soft soil roadbed, rib side slope of embankment, enhance isolation, inhibit ground deformation, prevent crack by reflection, increase strength of roadbed.

Application of Heat Bonded Geogrid With Geotextile

1. Reinforcement of road and railway, crack prevention, increase roadbed strength.

2. Reinforcement and stabilization of riverside, embankment and side slope.

3. Dyke reinforcement on soft ground for stress evenness, sedimentation adjustment, increase ofstability and loading capacity of fundus.

4. Reinforcement of the surface of road and bridge.

Specification of Heat Bonded Geogrid With Geotextile

| Classification | Type | Bearing strength(KN/m) | Bearing elongation(%) | Width | ||

| Composite PP Biaxial Geogrid With Nonwoven Geotextile | MD | CD | MD | CD | (m) | |

| GGM20/150 | ≥20 | ≥20 | 13 | 13 | 2~6 | |

| GGM30/150 | ≥30 | ≥30 | 13 | 13 | 2~6 | |

| GGM40/150 | ≥40 | ≥40 | 13 | 13 | 2~6 | |

- Products Geogrid Composite Geogrid Geotextile HDPE Geocell Geomembrane Composite Geomembrane HDPE GeonetDrainage GeocompositeErosion Control Mat

- Contact Us

- General Manager: Allen Mobile: +86 13854820689 Email: lianyiallen@126.com; chgeogrid@163.com WhatsApp +8613854820689 Wechat: 0086 13854820689 Skype: chgeogrid@hotmail.com

- Sales Director: Alice Mobile: +86 18953872761 Email: sdlianyigeogrid@hotmail.com Whatsapp: +86 18953872761 Wechat: 0086 18953872761

العربية

العربية Français

Français 한국어

한국어 Русский

Русский Español

Español English

English