- Home

- Products

- Geogrid

- Welded Geogrid

- Welding PET Geogrid

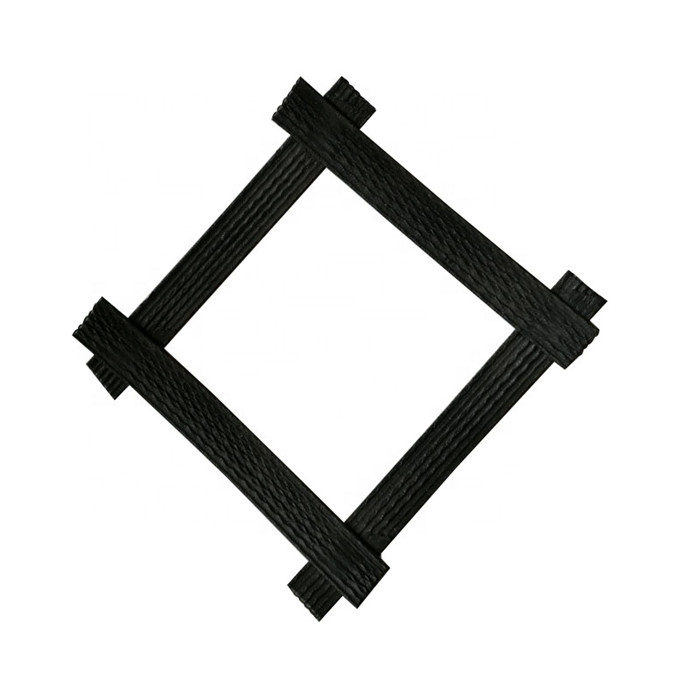

Welding PET Geogrid

Description

Welding PET Geogrid is high quality Welding PET geogrid with CE.

Description of Welding PET Geogrid

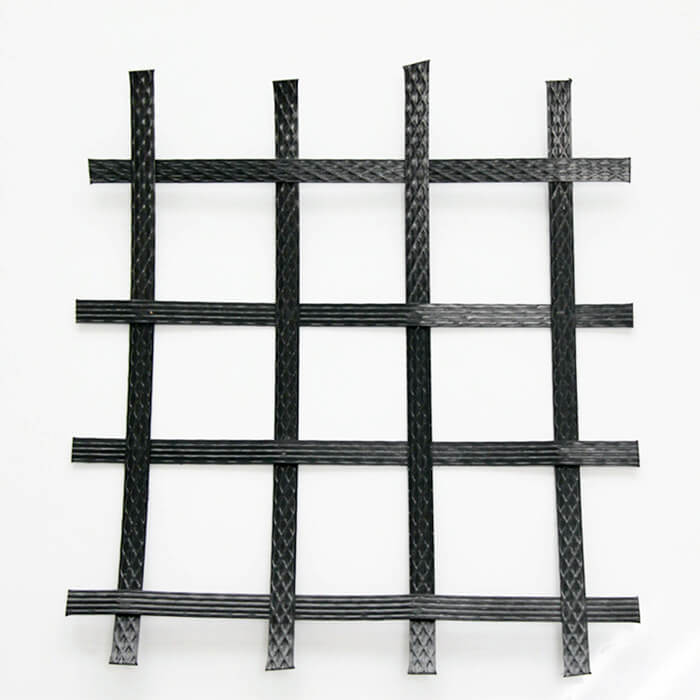

The tensile strength of steel-plastic composite geogrid is undertaken by high-strength steel-wire which are Weaven Horizontally and vertically. It creates high tensile modulus under low strain capacity. The cooperative performance of vertical and horizontal ribs could creat the most sufficient interlocking effect to soil.

Features of Welding PET Geogrid

1. The steel-wires of vertical and horizontal ribs of steel-plastic composite geogrid are knitted into webs. The outer coating is finished in one time. The steel-wires and the the outer coating play a coordinating role. The elongation rate at break is low ( less than 3% ).

2. By the treatment to plastic surfaces, the ribs are pressed into rough pattern to strengthen the roughness of the geogrid surface. This could improve the friction coefficient between the steel-plastic composite geogrid and soil.

3. The width of steel-plastic composite geogrid could reach 6m. The product has effective reinforcement effects.

4. The PP material of steel-plastic composite geogrid could ensure: it won't be eroded by acid, alkali, salt solution or oil under room temperature; It won't dissolved in water or destroyed by microorganisms. Meanwhile, the macromolecule properties of PE could resist aging caused by ultraviolet radiation.

5. The vertical and horizontal ribs cooperate with each other when pressed, and it won't crack or destroy at the nodes. In engineering constructions, the geogrids won't be subjected to ultraviolet and oxygen erosion under compaction by fillings. The geogrids can meet the requirements of permanent project construction.

Specification

| Project | GSZ30-30 | GSZ40-40 | GSZ50-50 | GSZ60-60 | GSZ80-80 | GSZ100-100 | GSZ150-150 | |

| Extends the rice stretch to submit every time the strength(KN/m)≥ | Longitudinal | 30 | 40 | 50 | 60 | 80 | 100 | 150 |

| Wang | 30 | 40 | 50 | 60 | 80 | 100 | 150 | |

| Submits the elongation ratio%≤ | Longitudinal | 3 | ||||||

| Wang | 3 | |||||||

| 2% Time elongation ratio drawing force (KN/m)≥ | Longitudinal | 27 | 32 | 45 | 54 | 67 | 84 | 127 |

| Wang | 27 | 32 | 45 | 54 | 67 | 84 | 127 | |

| Width (m) | 6.00+0.06 | |||||||

- Products Geogrid Composite Geogrid Geotextile HDPE Geocell Geomembrane Composite Geomembrane HDPE GeonetDrainage GeocompositeErosion Control Mat

- Contact Us

- General Manager: Allen Mobile: +86 13854820689 Email: lianyiallen@126.com; chgeogrid@163.com WhatsApp +8613854820689 Wechat: 0086 13854820689 Skype: chgeogrid@hotmail.com

- Sales Director: Alice Mobile: +86 18953872761 Email: sdlianyigeogrid@hotmail.com Whatsapp: +86 18953872761 Wechat: 0086 18953872761

العربية

العربية Français

Français 한국어

한국어 Русский

Русский Español

Español English

English