- Home

- Products

- Geogrid

- Polyester Geogrid

- Polyester Uniaxial Geogrid

Woven Polyester Geogrid

Description

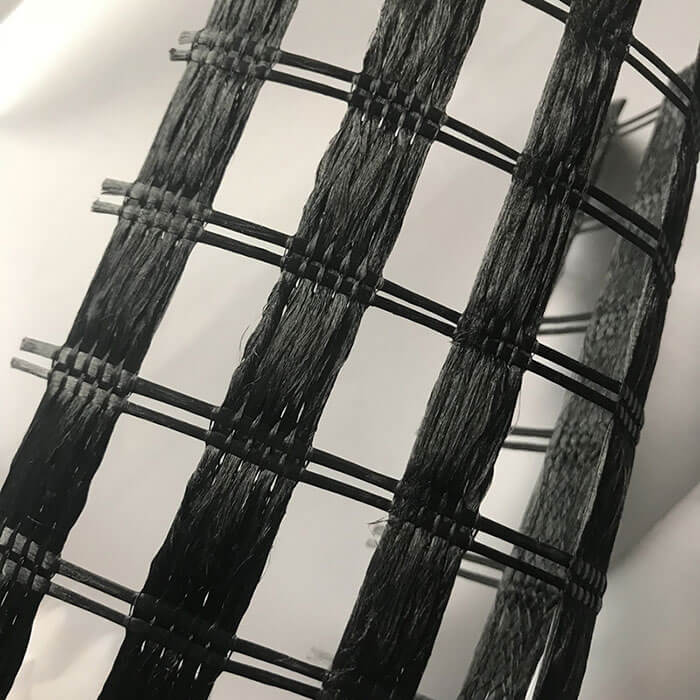

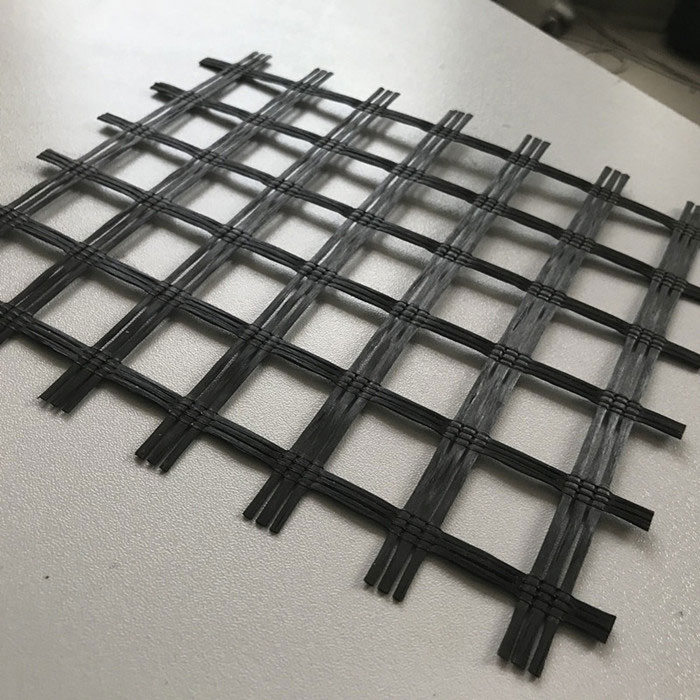

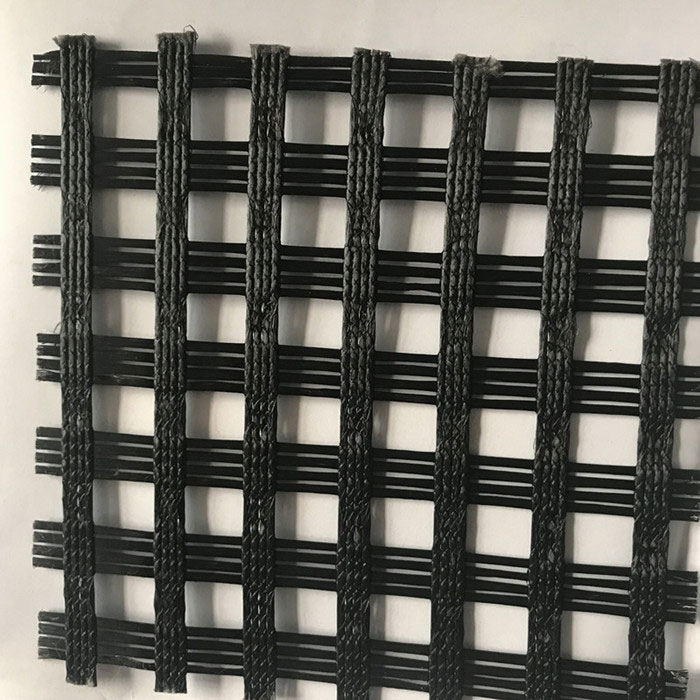

Woven Polyester Geogrid is made with polyester yarns that have a high molecular weight and extraordinary tensile strength.

Description of Woven Polyester Geogrid

Woven Polyester Geogrid is woven by high strength polymer yarns as per desired mesh sizes and strength from 20kN/m to 800kN/m(Biaxial type), 40-25kN/m to 600-400kN/m(Uniaxial type). Woven PET Grid is created through interlacing, usually at right angles, two or more yarns or filaments. Exterior of PET Grid is coated with polymer or nontoxic substance material for UV, acid and alkali resistance and prevents the bio-decomposition.PVC Coated Polyester Geogrid is widely introduced to the various fields of civil engineering, transportation engineering, and environment issues. The reinforced steep slopes, reinforced retaining earth walls, reinforced embankments, reinforced abutments and piers are typical applications where geogrids are used. The resulting grid structure possesses large openings that enhance interaction with filling material.

Specification of woven polyester geogrid

| Property | Unit | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET60-60 | PET80-80 | PET100-100 | PET400-400 | |

| Ultimate Tensile Strength | MD | KN/m | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 400 |

| CD | KN/m | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 400 | |

| Elongation at maximum load | MD | % | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 |

| CD | % | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | |

| Aperture size | mm | 12.7×12.7 25.4×25.4 40×40 | ||||||||

| Temperature Resistant | ℃ | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

| Resin Content | ℃ | ≦30 | ≦30 | ≦30 | ≦30 | ≦30 | ≦30 | ≦30 | ≦30 | |

| Glue Type | PVCsoakage | |||||||||

| resistance to installation damage | %SC/%SW/%GP | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | |

| resistance to long term degradation | % | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Roll Length | m | 50-200m | ||||||||

| Roll Width | m | 1-6m | ||||||||

| Property | Unit | PET40-25 | PET50-35 | PET60-30 | PET80-30 | PET100-30 | PET200-30 | PET400-30 | PET600-30 | |

| Ultimate Tensile Strength | MD | KN/m | 40 | 50 | 30 | 30 | 30 | 30 | 30 | 30 |

| CD | KN/m | 25 | 35 | 30 | 30 | 30 | 30 | 30 | 30 | |

| Elongation at maximum load | MD | % | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 |

| CD | % | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | |

| Aperture size | mm | 12.7×12.7 25.4×25.4 40×40 | ||||||||

| Temperature Resistant | ℃ | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

| Resin Content | ℃ | ≦30 | ≦30 | ≦30 | ≦30 | ≦30 | ≦30 | ≦30 | ≦30 | |

| Glue Type | PVCsoakage | |||||||||

| resistance to installation damage | %SC/%SW/%GP | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | |

| resistance to long term degradation | % | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Roll Length | m | 50-200m | ||||||||

| Roll Width | m | 1-6m | ||||||||

- Products Geogrid Composite Geogrid Geotextile HDPE Geocell Geomembrane Composite Geomembrane HDPE GeonetDrainage GeocompositeErosion Control Mat

- Contact Us

- General Manager: Allen Mobile: +86 13854820689 Email: lianyiallen@126.com; chgeogrid@163.com WhatsApp +8613854820689 Wechat: 0086 13854820689 Skype: chgeogrid@hotmail.com

- Sales Director: Alice Mobile: +86 18953872761 Email: sdlianyigeogrid@hotmail.com Whatsapp: +86 18953872761 Wechat: 0086 18953872761

العربية

العربية Français

Français 한국어

한국어 Русский

Русский Español

Español English

English